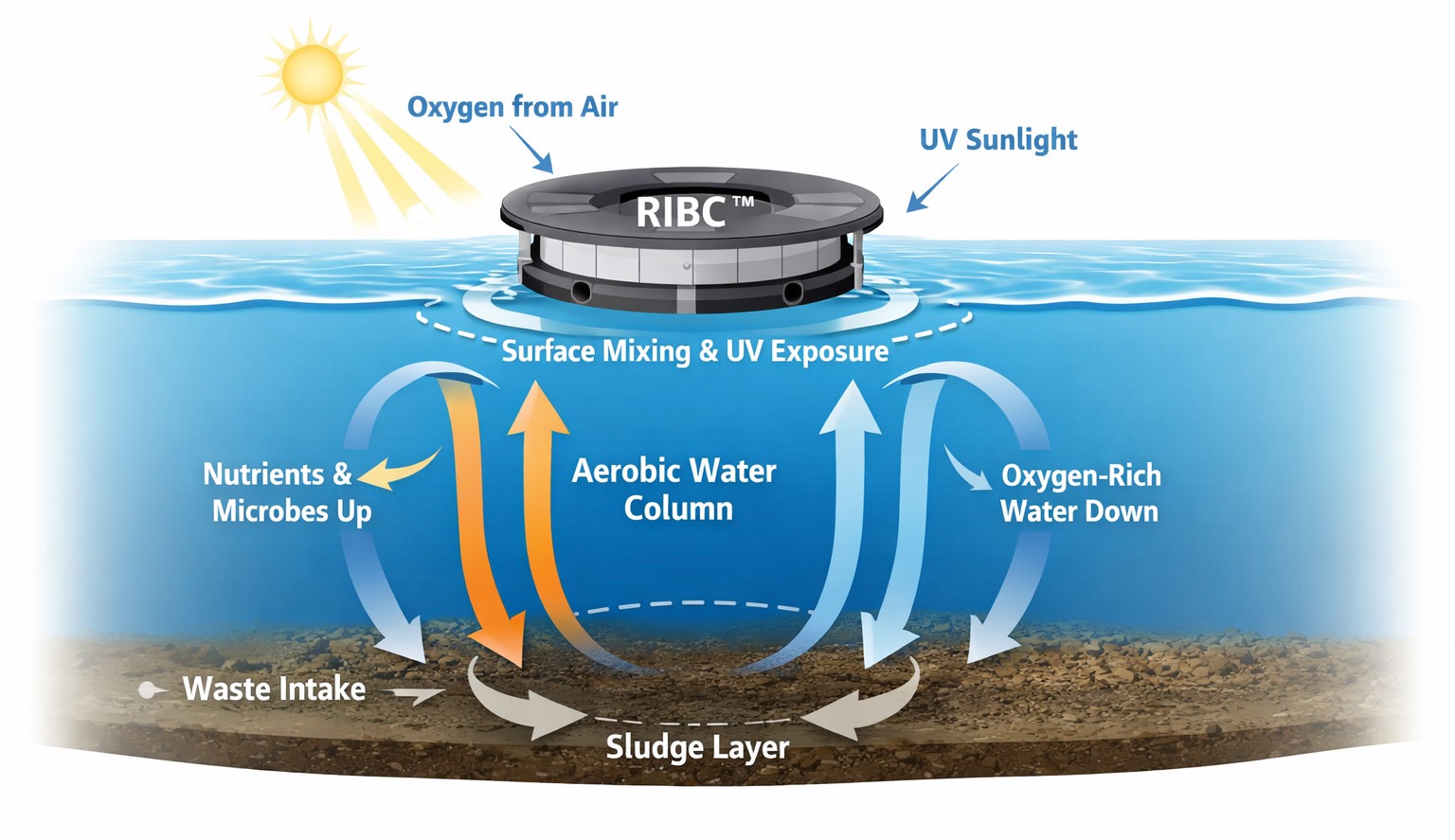

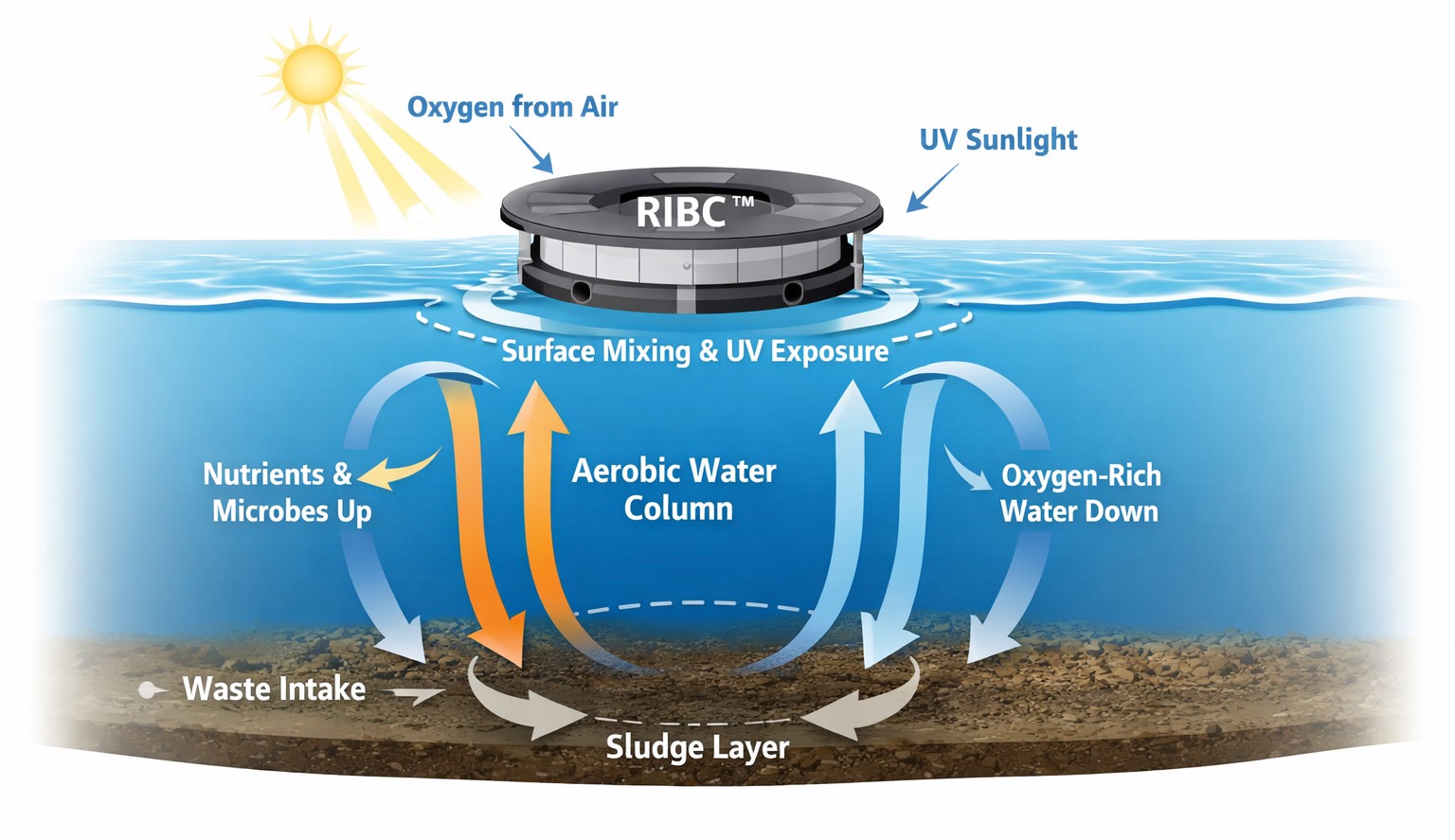

RIBC™ Mode of Action

Enviro.Farm’s core technology is built around the

RIBC™ (Rotating Inverse Biological Contactor) – a floating oxygenation and circulation system designed to transform organic waste into a stable, aerobic, nutrient-rich liquid through continuous circulation, oxygen transfer, and natural UV exposure.

Unlike conventional aeration, agitation, or blower-based systems, the RIBC™ maintains a fully aerobic water column by inducing a controlled, bottom-to-top circulation pattern that prevents sludge accumulation, odors, and greenhouse gas formation.

Toroidal Liquid Circulation™ (TLC™)

At the heart of the RIBC™ system is

Toroidal Liquid Circulation™ (TLC™) – a gentle but powerful vortex motion that continuously moves liquid throughout the entire treatment volume.

This circulation pattern:

- Sweeps inward across the bottom, gathering nutrients and organic material

- Lifts enzymatic nutrients upward to the surface

- Renews surface water exposure to atmospheric oxygen

- Returns oxygen-rich water and aerobic microbes back down across the bottom

By eliminating dead zones, TLC™ keeps the system fully aerobic and prevents the buildup of muck, sludge, and anaerobic conditions.

Oxygenation, UV Exposure, and Biological Action

As liquid reaches the surface, it is simultaneously exposed to:

- Atmospheric oxygen, increasing dissolved oxygen levels

- UV radiation from sunlight, which helps deactivate pathogens and degrade antibiotic residues

- Aerobic microbial activity, accelerating biological digestion

This continuous surface renewal allows microbes to efficiently break down large organic molecules while suppressing anaerobic organisms responsible for methane, ammonia, and hydrogen sulfide production.

Continuous Aerobic Treatment

The RIBC™ process combines continuous oxygenation with complete circulation to maintain a stable aerobic environment throughout the water column.

This helps prevent:

- Formation of offensive odors and gases

- Accumulation of sludge and solids

- Algal blooms and surface colonization

- Release of untreated nutrients and pathogens

With proper design, each unit circulates millions of gallons of water per hour, supporting sustained aerobic digestion across the entire treatment area.

Measurable System Performance

A single Enviro2Circulator™ (RIBC 9000 Series) delivers:

- Circulation exceeding 8.5 million gallons per hour

- Approximately 20 lbs of dissolved oxygen per hour

- Up to 240 lbs per day of BOD reduction per unit

- Conversion of sludge into approximately 99% true liquid, eliminating slurry handling

All of this is achieved using

fractional horsepower, resulting in significantly lower energy consumption compared to blower, aspirator, or venturi-based systems.

Additional Environmental Benefits

The RIBC™ Mode of Action delivers multiple downstream benefits, including:

- Elimination of odors and offensive gases

- Reduction of greenhouse gases, including methane and ammonia

- Deactivation of pathogens and antibiotic residues

- Suppression of harmful algal blooms

- Lower operating and maintenance costs

Together, these outcomes support a scalable, energy-efficient, and environmentally resilient approach to organic waste treatment.

Download RIBC™ Mode of Action (PDF)

Investing in Sustainable Dairy: Opportunities in the Evolving Cheese Industry

Investing in Sustainable Dairy: Opportunities in the Evolving Cheese Industry